DRUPS

Green Power International introduces an uninterrupted and limitless power solution with the Diesel Rotary UPS (DRUPS), powered by NO-BREAK KS® from esteemed DRUPS manufacturers, EURO-DIESEL of Belgium. Established in 1989, EURO-DIESEL has led the industry with its expertise in power products and Standby Generating sets, delivering an unparalleled Diesel Rotary Uninterruptible Power Supply system (DRUPS) known as NO-BREAK KS®.

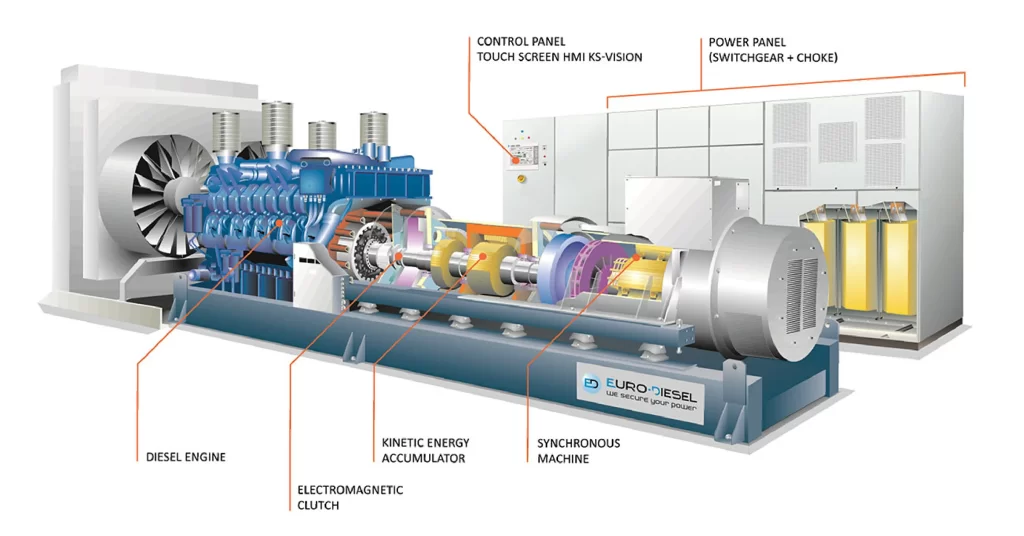

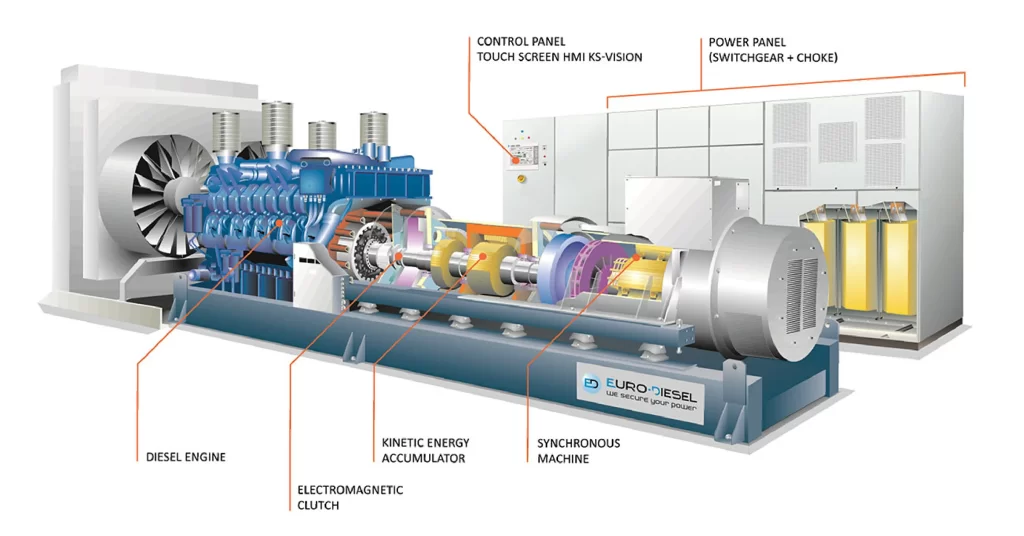

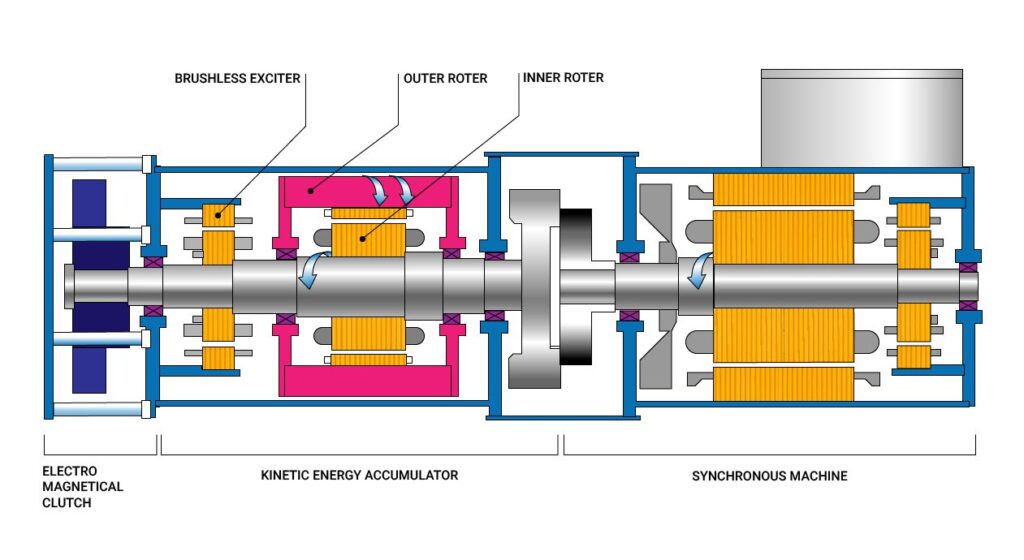

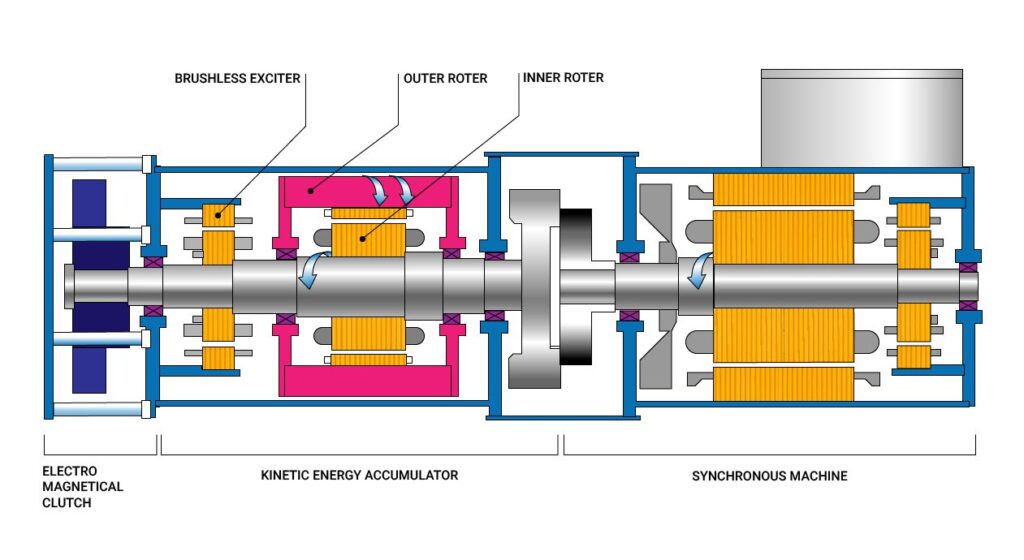

The advanced DRUPS system provides seamless and limitless power and revolutionizes Grid Supply Power Conditioning. It corrects voltage, enhances the Power Factor, filters out harmonics, and eliminates micro-cuts. The NO-BREAK KS® is ingeniously simple, featuring a Diesel Engine linked to a Stato-Alternator through an Electromagnetic Clutch. This Stato-Alternator amalgamates a Kinetic Energy Accumulator and a Synchronous machine. The NO-BREAK KS® also integrates control and choke/power panels.

Elevate your power resilience with DRUPS technology, with leading DRUPS manufacturers to bring you the NO-BREAK KS® solution.

How does it work?

- At the core of the NO-BREAK KS® lies its innovative kinetic energy accumulator, a brilliant yet straightforward mechanism for storing and releasing kinetic energy.

- This accumulator comprises two rotating components: the outer rotor rotates independently around the inner rotor (refer to the diagram below). The inner rotor, powered by the main shaft, turns at 1500 rpm and incorporates two sets of windings: a three-phase AC winding and a DC winding.

- This ingenious DRUPS technology, backed by Green Power International’s partnership with leading DRUPS manufacturers, ensures continuous power supply, offering reliability and efficiency in energy storage and utilization.

Energy storage

Conditioning Mode: The AC winding is energized, generating a rotating magnetic field that propels the outer rotor to a maximum speed of 3000 rpm. Despite this, the relative speed between the inner and outer bearing rings remains at 1500 rpm, aligned with the 1500 rpm rotation of the shaft. The outer rotor strategically accumulates kinetic energy as its kinetic energy proportionally escalates with its distance from the centre of rotation.

Energy retrieval

Independent Mode: Activating the DC winding establishes an electrical connection between the inner and outer rotors through induction. The kinetic energy stored in the outer rotor is then transmitted to the inner rotor, setting it in motion. This energy exchange is meticulously governed by precisely controlling the current input into the DC winding. Notably, the kinetic energy accumulator operates as a brushless system.

Conditioning Mode:

During the conditioning mode, when the mains supply operates within the defined tolerance range, the synchronous machine assumes the role of a motor. This facilitates the driving of the main shaft and, consequently, the accumulation of kinetic energy within the system. As the inner rotor achieves a rotation of 1500 rpm (50Hz), the outer rotor responds by reaching a maximum speed of 3000 rpm. The outcome of this process is the efficient storage of kinetic energy.

Independent Mode:

In the independent mode, activated in scenarios such as mains failure or voltage disturbances, the kinetic energy stored within the system undergoes a seamless transfer to the state-alternator, which takes on the role of a generator. This transition transpires without causing any disruption to the user experience. Subsequently, the diesel engine initiates its operation, engaging with the state alternator via an electromagnetic clutch. Energy transmission follows suit, progressing from the diesel engine to the synchronous machine and finally to the connected loads.

Sequence:

- QD1 Opens

- The kinetic energy harnessed from the outer rotor plays a pivotal role in maintaining the frequency at 50 Hz, held within a tight tolerance of +/- 1%.

- The engine begins its operation.

- The electromagnetic clutch closes.

- Upon the engine attaining a rotational speed of 1500 rpm, power transfer to the loads commences and persists until the mains supply is restored.

Transfer from Conditioning Mode to Independent Mode:

Visualized in the accompanying graph, the transition from conditioning to independent mode is showcased and then reversed. Throughout this process, the frequency is meticulously maintained within narrow tolerances. The speed of the accumulator gradually decreases, subsequently triggering the initiation of the diesel engine to provide power to the connected load. Should an unforeseen failure occur during the diesel engine start-up, the electromechanical clutch promptly closes after the QD1 opening, thus harnessing the kinetic energy of the accumulator to commence the diesel engine. This redundancy establishes the NO-BREAK KS® as equipped with a dual-start capability, offering an additional guarantee for engine activation

Mains Return: Back to Conditioning Mode:

Upon the restoration of the mains supply, the NO-BREAK KS® seamlessly synchronizes with it. The outer rotor swiftly re-accelerates to its designated speed. Upon achieving the rated kinetic energy storage, QD1 closes. The electromagnetic clutch disengages, thereby facilitating the closure of the clutch. Subsequently, the diesel engine operates at an idle speed, serving the purpose of cooling before eventually coming to a halt. This comprehensive system ensures that critical loads are safeguarded against an unlimited number of repeated mains failures.

KS-VISION®

Designed to facilitate effortless operation and monitoring of each NO-BREAK KS®, the KS-VISION® serves as a cutting-edge touchscreen HMI (Human-Machine Interface) control system. This user-friendly interface offers a seamless experience, ensuring efficient management of the DRUPS system.

In a dedicated effort to ensure exceptional reliability and long-term availability, EURO-DIESEL collaborated with select partners to develop the state-of-the-art Digital Control Module (DCM) that underpins the KS-VISION®. This module guarantees safe and dependable DRUPS operation, ensuring an uninterrupted power supply to critical loads, even in the face of challenging conditions.

Each NO-BREAK KS® control panel is equipped with the KS-VISION® as a standard component. Beyond local access, this innovative system can be interacted with through diverse means, including modems, Modbus/Profibus protocols, and even the World Wide Web. Remarkably, the NO-BREAK KS® remains fully functional irrespective of the local HMI status.

KS-VISION® Features:

- A 12" Colour Touchscreen for intuitive interaction.

- Seamless Ethernet link to the PLC.

- Web-based monitoring for remote management.

- Dynamic IP address for external communication.

- Convenient front-panel USB plug-in for easy connectivity.

- Redundant design to eliminate single points of failure.

- Automatic recognition of single and parallel system configurations.

- Intelligent Diesel starts reduction.

- Data generation for vital parameters: input/output voltage, frequency, power demand (kW, kVA, kVAr), current, and power factor.

- System mode information: conditioning mode, independent mode, and bypass mode.

- Access to alarms, statuses, and controls.

- Customizable settings for languages, time, communication protocols, and system tests.

DRUPS System Advantages: Empowering Efficient and Reliable Power

Experience the superiority of the DRUPS system with the NO-BREAK KS®, a testament to cutting-edge power solutions that redefine efficiency and reliability in the market. While operating in conditioning mode, even the most efficient DRUPS systems consume energy. Remarkably, the NO-BREAK KS® stands apart by consuming minimal energy, setting new standards for clean and conditioned power supply to critical loads.

Electrical Advantages:

- Highest Efficiency: The NO-BREAK KS® emerges as the most efficient system in the market, boasting an efficiency rating of over 96%.

- Reliability: Rooted in its meticulous design, the NO-BREAK KS® excels in reliability. Its low component count and operational speed result in an unmatched Mean Time Between Failures (MTBF) in the industry.

- Elimination of Mains Perturbations: Irksome voltage dips, spikes, switching pulses, micro-cuts, and more are automatically eradicated across all operational modes.

- Load Voltage Regulation: The protected busbar's voltage is meticulously regulated within a narrow ±1% range, even in the face of upstream voltage fluctuations ranging from +10% to -30%.

- Power Factor Correction: The NO-BREAK KS® delivers reactive power and enhances the power factor on the primary side, rendering capacitor banks unnecessary. By virtually achieving a unity input power factor, the NO-BREAK KS® significantly reduces electricity bills.

- Harmonics Filtration: The NO-BREAK KS® serves as an impeccable filter against all forms of disturbances. It safeguards loads from mains-driven harmonics and preemptively thwarts mains disruptions arising from load harmonics.

- Short Circuits Clearing: An exceptional feature of the NO-BREAK KS®, it allows the efficient clearing of short circuits on downstream feeders without resorting to bypass mechanisms.

Elevate your power experience with the exceptional DRUPS technology of the NO-BREAK KS® – a product of Green Power International, collaboratively crafted with distinguished DRUPS manufacturers.

Mechanical Advantages: Pioneering Efficiency and Robust Design

Explore the mechanical prowess of the NO-BREAK KS®, a revolutionary DRUPS solution engineered for efficiency and durability. Experience the following mechanical advantages that set the NO-BREAK KS® apart:

- Small Footprint: The NO-BREAK KS® achieves an impressive capacity of up to 2500 kVA (50Hz) per unit, offering up to 50% floor space savings in comparison to static UPS designs.

- Brushless Operation: The brushless operation of the NO-BREAK KS® eliminates the challenges associated with brushes and slip rings, ensuring smoother performance and reduced maintenance concerns.

- Unstressed Bearings: With a maximum bearing speed below 1500 rpm, the NO-BREAK KS® guarantees lower operating temperatures, enhanced efficiencies, and a significantly prolonged bearing lifespan.

- Monobloc Design: Featuring a robust monobloc design, the NO-BREAK KS® boasts directly coupled machines that contribute to exceptional sturdiness. This design negates the need for critical laser alignment inspections, both in the factory and on-site.

- Redundant Starting System: The NO-BREAK KS® is equipped with a redundant starting system, harnessing the kinetic energy of the outer rotor to activate the diesel engine mechanically. This dual mechanism ensures dependable engine activation.

Discover the NO-BREAK KS® – an embodiment of cutting-edge mechanical engineering from Green Power International, in collaboration with eminent DRUPS manufacturers.

Product Range

- NO-BREAK KS®7e - 2750kVA (50Hz): The epitome of efficiency, the NO-BREAK KS®7e stands as the most efficient system on the market (>96%). With EURO-DIESEL's latest advancements, this next-gen Diesel Rotary Uninterruptible Power Supply system optimizes power density and footprint, delivering up to 2750 kVA (50Hz) per unit. A game-changer for energy-saving data centres.

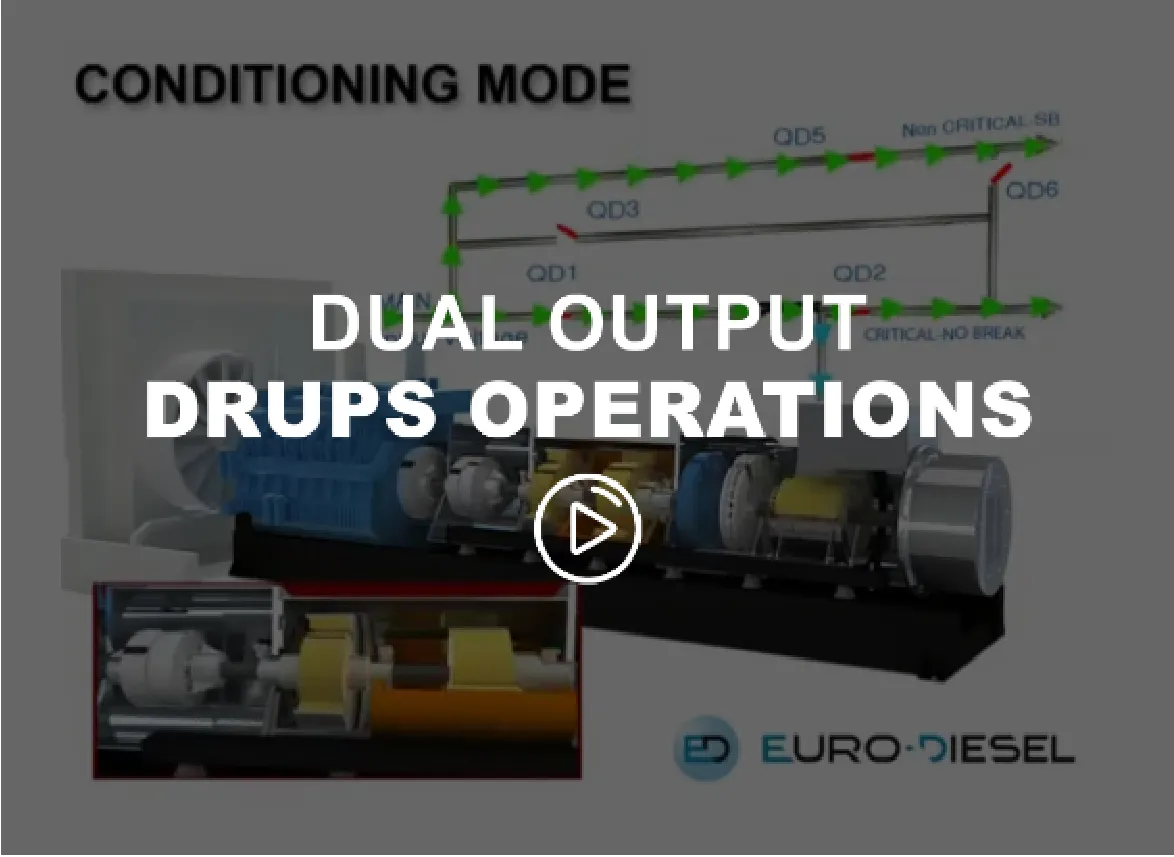

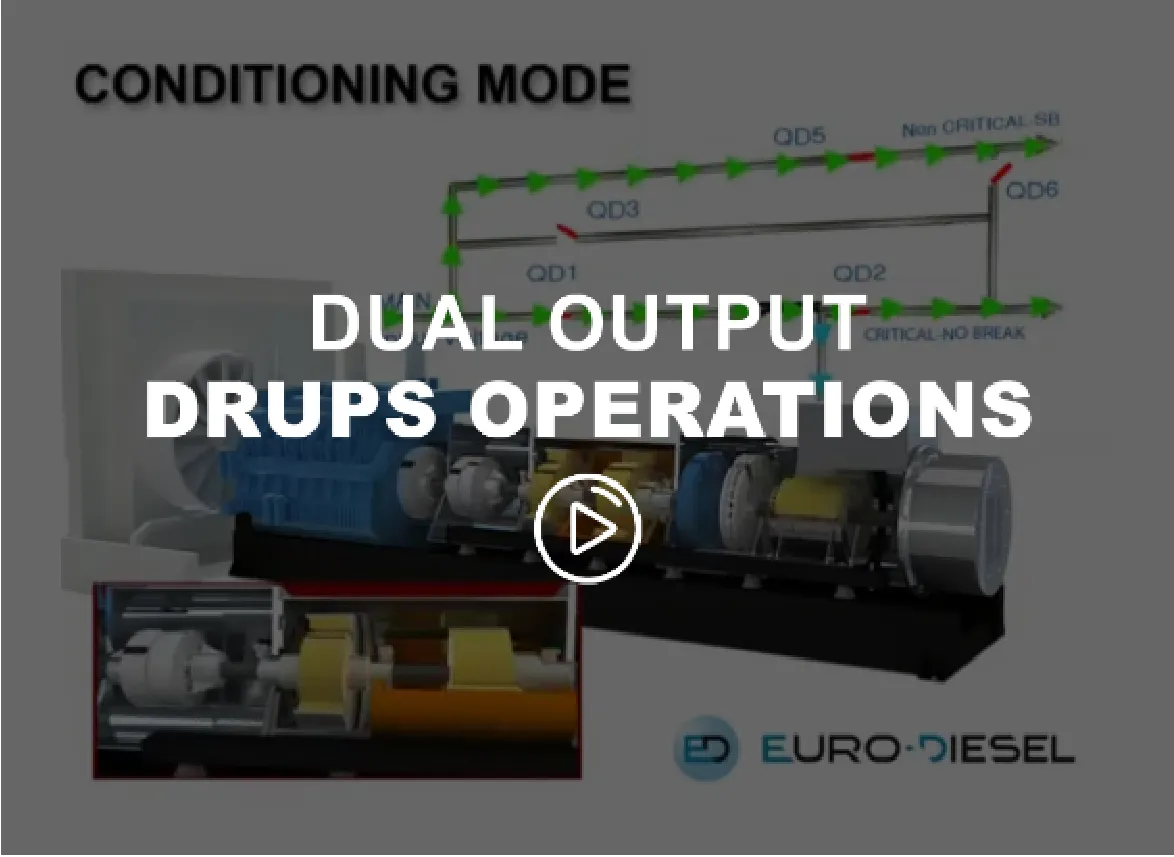

- NO-BREAK KS®7E-SB - 2750kVA (50Hz): Embracing load diversity, the NO-BREAK KS®7e-SB (dual output version) efficiently delivers 2750 kVA per unit, catering to both critical and non-critical loads seamlessly.

- NO-BREAK KS®5 - 200 to 2500kVA (50Hz): Crafted for uncompromising power quality, robustness, and reliability, the NO-BREAK KS®5 range safeguards critical loads from 200kVA onwards, seamlessly integrating into existing facilities while meeting unique requirements.

- NO-BREAK KS®5 - SB - 200-2500kVA (50Hz): Addressing dynamic load needs, the NO-BREAK KS®5-SB smartly powers critical and non-critical loads, eliminating the need for additional generators, saving space, and reducing costs.

- NO-BREAK KS®4 - 100 - 200kVA (50Hz): Ideal for varied industries, the compact NO-BREAK KS®4 presents a flexible DRUPS solution featuring easy installation and operation, making it an apt choice for diverse sectors.

- SYNCHROSTA JS® - 200-2500kVA (50Hz): Tackle power quality issues with SYNCHROSTA JS®, a mains conditioner and short outage solution. By mitigating disruptions, enhancing power factor, isolating from harmonics, and offering protection, this system empowers stability and resilience.

By installing the SYNCHROSTA® JS, these disruptions are dealt with, and in addition, you gain other benefits:

- Short power transfer is sometimes sufficient to eliminate the need for longer-term backup strategies.

- The system works as a synchronous compensator and improves the power factor.

- It isolates the load from mains that carry harmonics and prevents main disturbances caused by load harmonics.

- The load is protected from spikes and switching pulses.

- Fast clearing of downstream short circuits is enabled.

Conditioning Mode:

During the conditioning mode, when the mains supply operates within the defined tolerance range, the synchronous machine assumes the role of a motor. This facilitates the driving of the main shaft and, consequently, the accumulation of kinetic energy within the system. As the inner rotor achieves a rotation of 1500 rpm (50Hz), the outer rotor responds by reaching a maximum speed of 3000 rpm. The outcome of this process is the efficient storage of kinetic energy.

Independent Mode:

In the independent mode, activated in scenarios such as mains failure or voltage disturbances, the kinetic energy stored within the system undergoes a seamless transfer to the state-alternator, which takes on the role of a generator. This transition transpires without causing any disruption to the user experience. Subsequently, the diesel engine initiates its operation, engaging with the state alternator via an electromagnetic clutch. Energy transmission follows suit, progressing from the diesel engine to the synchronous machine and finally to the connected loads.

Sequence:

- QD1 Opens

- The kinetic energy harnessed from the outer rotor plays a pivotal role in maintaining the frequency at 50 Hz, held within a tight tolerance of +/- 1%.

- The engine begins its operation.

- The electromagnetic clutch closes.

- Upon the engine attaining a rotational speed of 1500 rpm, power transfer to the loads commences and persists until the mains supply is restored.

Transfer from Conditioning Mode to Independent Mode:

Visualized in the accompanying graph, the transition from conditioning to independent mode is showcased and then reversed. Throughout this process, the frequency is meticulously maintained within narrow tolerances. The speed of the accumulator gradually decreases, subsequently triggering the initiation of the diesel engine to provide power to the connected load. Should an unforeseen failure occur during the diesel engine start-up, the electromechanical clutch promptly closes after the QD1 opening, thus harnessing the kinetic energy of the accumulator to commence the diesel engine. This redundancy establishes the NO-BREAK KS® as equipped with a dual-start capability, offering an additional guarantee for engine activation.

Mains Return: Back to Conditioning Mode:

Upon the restoration of the mains supply, the NO-BREAK KS® seamlessly synchronizes with it. The outer rotor swiftly re-accelerates to its designated speed. Upon achieving the rated kinetic energy storage, QD1 closes. The electromagnetic clutch disengages, thereby facilitating the closure of the clutch. Subsequently, the diesel engine operates at an idle speed, serving the purpose of cooling before eventually coming to a halt. This comprehensive system ensures that critical loads are safeguarded against an unlimited number of repeated mains failures.

KS-VISION®

Designed to facilitate effortless operation and monitoring of each NO-BREAK KS®, the KS-VISION® serves as a cutting-edge touchscreen HMI (Human-Machine Interface) control system. This user-friendly interface offers a seamless experience, ensuring efficient management of the DRUPS system.

In a dedicated effort to ensure exceptional reliability and long-term availability, EURO-DIESEL collaborated with select partners to develop the state-of-the-art Digital Control Module (DCM) that underpins the KS-VISION®. This module guarantees safe and dependable DRUPS operation, ensuring an uninterrupted power supply to critical loads, even in the face of challenging conditions.

Each NO-BREAK KS® control panel is equipped with the KS-VISION® as a standard component. Beyond local access, this innovative system can be interacted with through diverse means, including modems, Modbus/Profibus protocols, and even the World Wide Web. Remarkably, the NO-BREAK KS® remains fully functional irrespective of the local HMI status.

KS-VISION® Features:

- A 12" Colour Touchscreen for intuitive interaction.

- Seamless Ethernet link to the PLC.

- Web-based monitoring for remote management.

- Dynamic IP address for external communication.

- Convenient front-panel USB plug-in for easy connectivity.

- Redundant design to eliminate single points of failure.

- Automatic recognition of single and parallel system configurations.

- Intelligent Diesel starts reduction.

- Data generation for vital parameters: input/output voltage, frequency, power demand (kW, kVA, kVAr), current, and power factor.

- System mode information: conditioning mode, independent mode, and bypass mode.

- Access to alarms, statuses, and controls.

- Customizable settings for languages, time, communication protocols, and system tests.

DRUPS System Advantages: Empowering Efficient and Reliable Power

Experience the superiority of the DRUPS system with the NO-BREAK KS®, a testament to cutting-edge power solutions that redefine efficiency and reliability in the market. While operating in conditioning mode, even the most efficient DRUPS systems consume energy. Remarkably, the NO-BREAK KS® stands apart by consuming minimal energy, setting new standards for clean and conditioned power supply to critical loads.

Electrical Advantages:

- Highest Efficiency: The NO-BREAK KS® emerges as the most efficient system in the market, boasting an efficiency rating of over 96%.

- Reliability: Rooted in its meticulous design, the NO-BREAK KS® excels in reliability. Its low component count and operational speed result in an unmatched Mean Time Between Failures (MTBF) in the industry.

- Elimination of Mains Perturbations: Irksome voltage dips, spikes, switching pulses, micro-cuts, and more are automatically eradicated across all operational modes.

- Load Voltage Regulation: The protected busbar's voltage is meticulously regulated within a narrow ±1% range, even in the face of upstream voltage fluctuations ranging from +10% to -30%.

- Power Factor Correction: The NO-BREAK KS® delivers reactive power and enhances the power factor on the primary side, rendering capacitor banks unnecessary. By virtually achieving a unity input power factor, the NO-BREAK KS® significantly reduces electricity bills.

- Harmonics Filtration: The NO-BREAK KS® serves as an impeccable filter against all forms of disturbances. It safeguards loads from mains-driven harmonics and preemptively thwarts mains disruptions arising from load harmonics.

- Short Circuits Clearing: An exceptional feature of the NO-BREAK KS®, it allows the efficient clearing of short circuits on downstream feeders without resorting to bypass mechanisms.

Elevate your power experience with the exceptional DRUPS technology of the NO-BREAK KS® – a product of Green Power International, collaboratively crafted with distinguished DRUPS manufacturers.

Mechanical Advantages: Pioneering Efficiency and Robust Design

Explore the mechanical prowess of the NO-BREAK KS®, a revolutionary DRUPS solution engineered for efficiency and durability. Experience the following mechanical advantages that set the NO-BREAK KS® apart:

- Small Footprint: The NO-BREAK KS® achieves an impressive capacity of up to 2500 kVA (50Hz) per unit, offering up to 50% floor space savings in comparison to static UPS designs.

- Brushless Operation: The brushless operation of the NO-BREAK KS® eliminates the challenges associated with brushes and slip rings, ensuring smoother performance and reduced maintenance concerns.

- Unstressed Bearings: With a maximum bearing speed below 1500 rpm, the NO-BREAK KS® guarantees lower operating temperatures, enhanced efficiencies, and a significantly prolonged bearing lifespan.

- Monobloc Design: Featuring a robust monobloc design, the NO-BREAK KS® boasts directly coupled machines that contribute to exceptional sturdiness. This design negates the need for critical laser alignment inspections, both in the factory and on-site.

- Redundant Starting System: The NO-BREAK KS® is equipped with a redundant starting system, harnessing the kinetic energy of the outer rotor to activate the diesel engine mechanically. This dual mechanism ensures dependable engine activation.

Discover the NO-BREAK KS® – an embodiment of cutting-edge mechanical engineering from Green Power International, in collaboration with eminent DRUPS manufacturers.

Product Range

- NO-BREAK KS®7e - 2750kVA (50Hz): The epitome of efficiency, the NO-BREAK KS®7e stands as the most efficient system on the market (>96%). With EURO-DIESEL's latest advancements, this next-gen Diesel Rotary Uninterruptible Power Supply system optimizes power density and footprint, delivering up to 2750 kVA (50Hz) per unit. A game-changer for energy-saving data centres.

- NO-BREAK KS®7E-SB - 2750kVA (50Hz): Embracing load diversity, the NO-BREAK KS®7e-SB (dual output version) efficiently delivers 2750 kVA per unit, catering to both critical and non-critical loads seamlessly.

- NO-BREAK KS®5 - 200 to 2500kVA (50Hz): Crafted for uncompromising power quality, robustness, and reliability, the NO-BREAK KS®5 range safeguards critical loads from 200kVA onwards, seamlessly integrating into existing facilities while meeting unique requirements.

- NO-BREAK KS®5 - SB - 200-2500kVA (50Hz): Addressing dynamic load needs, the NO-BREAK KS®5-SB smartly powers critical and non-critical loads, eliminating the need for additional generators, saving space, and reducing costs.

- NO-BREAK KS®4 - 100 - 200kVA (50Hz): Ideal for varied industries, the compact NO-BREAK KS®4 presents a flexible DRUPS solution featuring easy installation and operation, making it an apt choice for diverse sectors.

- SYNCHROSTA JS® - 200-2500kVA (50Hz): Tackle power quality issues with SYNCHROSTA JS®, a mains conditioner and short outage solution. By mitigating disruptions, enhancing power factor, isolating from harmonics, and offering protection, this system empowers stability and resilience.

By installing the SYNCHROSTA® JS, these disruptions are dealt with, and in addition, you gain other benefits:

- Short power transfer is sometimes sufficient to eliminate the need for longer-term backup strategies.

- The system works as a synchronous compensator and improves the power factor.

- It isolates the load from mains that carry harmonics and prevents main disturbances caused by load harmonics.

- The load is protected from spikes and switching pulses.

- Fast clearing of downstream short circuits is enabled.

Green Power International’s partnership with top Diesel Rotary Uninterruptible Power Supply manufacturers supports the innovative DRUPS technology, guaranteeing uninterrupted power supply diesel engines while maximizing energy storage and utilization efficiency. As the outer rotor rapidly regains its designated speed, it reaches the intended kinetic energy storage level, allowing the diesel engine to transition to an idle state for cooling before ultimately shutting down.