TCG 3016 Series

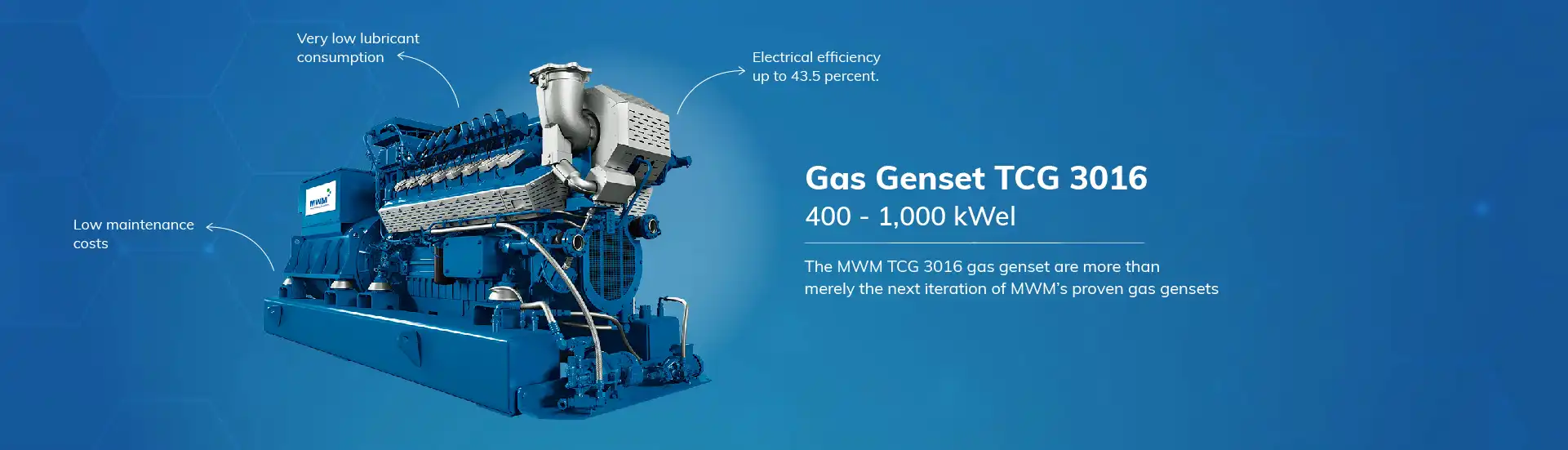

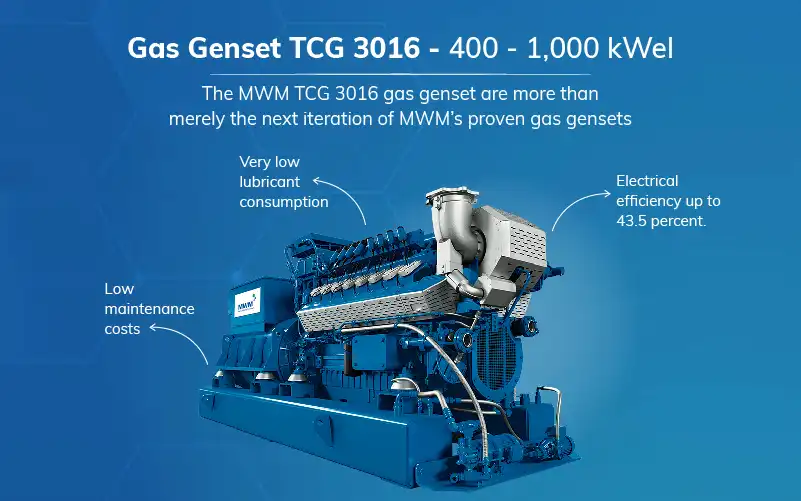

Green Power International boasts the distributorship of the MWM TCG 3016 gas engines that transcend the mere evolution of MWM’s gas gensets; they epitomise an entirely novel development meticulously designed to meet the challenges of Industry 4.0 and the evolving dynamics of today’s global value chain-oriented market. These cutting-edge sustainable gas engines, offered within the output range of 400 kWe to 1,000 kWe, are founded upon exceptional efficiency, unwavering reliability, remarkable flexibility, and a relentless commitment to environmental compatibility and GHG reductions.

Pursuing outstanding efficiency is evident through significantly reduced fuel costs, aligning with modern demands for cost-effective operations. The engines also exhibit deficient lubricant consumption, embodying sustainability and operational excellence.

Incorporating the digitized power plant control TPEM is an undeniable testament to innovation. This advanced technology exemplifies the convergence of digitization and operational management, enabling these engines to stand as beacons of efficiency and precision in power generation.

MWM TCG 3016 Gas Engine

Efficiency Goes Digital: The New Standard Robust, efficient, digital.

- Output: 400 kWe to 1,000 kWe.

- Up to 43.5% electrical efficiency

- Reduced installation and operating costs

- Enhanced reliability and availability

- Low maintenance costs, extended intervals

- Minimal lubricant consumption and user-friendly oil management

- The TCG 3016 V16 S is specifically optimised for the 1 MWe capacity range, with high stress tolerance for optimum availability and long functional life.

Green Power International takes pride in being a small part of MWM’s legacy as a gas engine manufacturer that is at its pinnacle in the MWM TCG 3016 gas engines. Embracing innovation, sustainability, and adaptability, these engines epitomise the transformative potential of power generators in the age of Industry 4.0 and the global value chain.

Optimized Lubricant Management

- TCG 3016 gas engine: remarkable oil consumption at 0.1 g/kWh, the class's lowest.

- Extended oil change intervals via innovative lubricant control.

- Natural gas and biogas have lubricant change intervals of up to 4,000 operation hours.

- Up to 66% lower lubricant consumption compared to rivals.

- Achieving the lowest specific lube oil consumption in its category.

- Oil changes are required after a thorough oil analysis.

Economical, Efficient, and Complete

MWM Gas Genset boasts a remarkable legacy of over 150 years in distributed energy generation, setting a benchmark for cutting-edge solutions in the industry.

Caterpillar revolutionizes energy control with the Total Plant & Energy Management (TPEM) digital power plant system.

- Simplified Control: TPEM integrates all power plant data, minimising additional systems.

- Unified Interface: Complete power plant control through one user interface.

- Remote Management: Achieve remote power plant control both on-site and through a VPN connection, featuring the "TPEM Remote Client" visualization.

- Security Emphasis: ISO 27001 standards, certified TÜV safety chain for cogeneration monitoring.

- Tailored Solutions: Custom setups, modular structures for diverse electric power applications.

- Efficiency at its Core: Ensures high thermal efficiency, remote management, and maximal genset reliability.

- Optimisation Insights: Data analysis for power plant enhancements, life cycle history for data access.

These features, seamlessly integrated with MWM’s eco-friendly gas gensets, underscore Caterpillar’s prowess as a leading gas genset manufacturer.

High Efficiency, Low Operating Costs

- Top-tier efficiency in its class via extended maintenance intervals of 80,000 operating hours for natural gas & high electrical efficiency of up to 43.5%.

- Sole gas engines unite efficiency and robustness to an exceptional degree.

- Optimized combustion elevates electrical efficiency while reducing component stress and vibration

- Versatile fuel compatibility: low gas consumption, suitable for various gas types, including natural gas, biogas, landfill gas, sewage gas, mine gas, and more.

Reduced Installation and Building Costs

- Smaller setup area than comparable gensets due to integrated tanks and a compact design for daily refilling.

- The flanged genset concept facilitates direct vibration decoupling between the gas engine and base frame, resulting in lower setup costs.

- Reduced investment costs are due to the expanded product scope and the innovative TPEM (Total Plant and Energy Management) digital power plant control.

- Optimised combustion chamber geometry leads to higher mixture circuit temperatures, reducing dry cooler investment costs and ensuring steady combustion.

- Additional benefits and technological enhancements include a water-cooled turbocharger, optimized fuel gas mix flow control, and improved gas engine oil management.

Performance Data

>> Natural gas applications, NOx ≤ 500 mg/Nm3 *

| Engine Type | TCG 3016 V08 | TCG 3016 V12 | TCG 3016 V16 | |

|---|---|---|---|---|

| Electrical Output | kW | 400 | 600 | 800 |

| Medium Effective Pressure | bar | 18.9 | 18.9 | 18.8 |

| Thermal Output ± 8% | kW | 404 | 618 | 821 |

| Electrical efficiency | % | 43.1 | 43.3 | 43.5 |

| Thermal Efficiency | % | 43.6 | 44.6 | 44.6 |

| Overall Efficiency | % | 86.7 | 87.9 | 88.1 |

>> Biogas, landfill gas, and sewage gas applications, NOx ≤ 500 mg/Nm3 *

| Engine Type | TCG 3016 V08 | TCG 3016 V12 | TCG 3016 V16 | |

|---|---|---|---|---|

| Electrical Output | kW | 400 | 600 | 800 |

| Medium Effective Pressure | bar | 18.9 | 18.9 | 18.8 |

| Thermal Output ± 8% | kW | 394 | 599 | 791 |

| Electrical efficiency | % | 42.8 | 42.9 | 43.1 |

| Thermal Efficiency | % | 42.2 | 42.8 | 42.6 |

| Overall Efficiency | % | 85.0 | 85.7 | 85.7 |

- NOx ≤ 500 mg/Nm3; exhaust gas dry at 5 % O2.

- Electrical output according to ISO 3046-1 at U = 11 kV, p.f = 1.0 for 50 Hz and a minimum methane number of MN 70 for natural gas

- Thermal output values are based on Exhaust gas cooled to 120°C for natural gas and 180°C for biogas.

- The values given above are for information purposes only and not binding. The information given in the offer is decisive.

Specifications and Dimensions

>> Natural gas applications, NOx ≤ 500 mg/Nm3 *

| Engine Type | TCG 3016 V08 | TCG 3016 V12 | TCG 3016 V16 | |

|---|---|---|---|---|

| Electrical Output | kW | 400 | 600 | 800 |

| Medium Effective Pressure | bar | 18.9 | 18.9 | 18.8 |

| Thermal Output ± 8% | kW | 404 | 618 | 821 |

| Electrical efficiency | % | 43.1 | 43.3 | 43.5 |

| Thermal Efficiency | % | 43.6 | 44.6 | 44.6 |

| Overall Efficiency | % | 86.7 | 87.9 | 88.1 |

>> Biogas, landfill gas, and sewage gas applications, NOx ≤ 500 mg/Nm3 *

Notes:- The values given above are for information purposes only and not binding. The information given in the offer is decisive.

Performance Data

>> Natural gas applications, NOx ≤ 500 mg/Nm3 *

| Engine Type | TCG 3016 V08 | TCG 3016 V12 | TCG 3016 V16 | |

|---|---|---|---|---|

| Electrical Output | kW | 400 | 600 | 800 |

| Medium Effective Pressure | bar | 18.9 | 18.9 | 18.8 |

| Thermal Output ± 8% | kW | 404 | 618 | 821 |

| Electrical efficiency | % | 43.1 | 43.3 | 43.5 |

| Thermal Efficiency | % | 43.6 | 44.6 | 44.6 |

| Overall Efficiency | % | 86.7 | 87.9 | 88.1 |

>> Biogas, landfill gas, and sewage gas applications, NOx ≤ 500 mg/Nm3 *

| Engine Type | TCG 3016 V08 | TCG 3016 V12 | TCG 3016 V16 | |

|---|---|---|---|---|

| Electrical Output | kW | 400 | 600 | 800 |

| Medium Effective Pressure | bar | 18.9 | 18.9 | 18.8 |

| Thermal Output ± 8% | kW | 394 | 599 | 791 |

| Electrical efficiency | % | 42.8 | 42.9 | 43.1 |

| Thermal Efficiency | % | 42.2 | 42.8 | 42.6 |

| Overall Efficiency | % | 85.0 | 85.7 | 85.7 |

- NOx ≤ 500 mg/Nm3; exhaust gas dry at 5 % O2.

- Electrical output according to ISO 3046-1 at U = 11 kV, p.f = 1.0 for 50 Hz and a minimum methane number of MN 70 for natural gas

- Thermal output values are based on Exhaust gas cooled to 120°C for natural gas and 180°C for biogas.

- The values given above are for information purposes only and not binding. The information given in the offer is decisive.

Specifications and Dimensions

>> Natural gas applications, NOx ≤ 500 mg/Nm3 *

| Engine Type | TCG 3016 V08 | TCG 3016 V12 | TCG 3016 V16 | |

|---|---|---|---|---|

| Electrical Output | kW | 400 | 600 | 800 |

| Medium Effective Pressure | bar | 18.9 | 18.9 | 18.8 |

| Thermal Output ± 8% | kW | 404 | 618 | 821 |

| Electrical efficiency | % | 43.1 | 43.3 | 43.5 |

| Thermal Efficiency | % | 43.6 | 44.6 | 44.6 |

| Overall Efficiency | % | 86.7 | 87.9 | 88.1 |

>> Biogas, landfill gas, and sewage gas applications, NOx ≤ 500 mg/Nm3 *

Notes:- The values given above are for information purposes only and not binding. The information given in the offer is decisive.